Vehicle Mechanical - Summer 2022

GoKart

Design and build an electric go-kart durable enough to survive multiple laps in a race with classmates. The end vehicle should exhibit good handling and performance characteristics in-line with commercially available options.

Project Highlights

The goal of this class was to enhance our comprehension of vehicle dynamics and its practical application in areas such as handling, packaging, powertrain efficiency, and durability. Teams of two were given 14 weeks to design and build operational go-karts that met rigorous design criteria.

Powertrain

Although all 6 teams were tasked with designing entirely unique karts, one thing that was identical on all six was the propulsion system, a heavy-duty power drill. Aside from leveling the playing field, the drill provided unique challenges stemming from linkages and chassis rigidity.

Chassis

This was by far the project's greatest challenge, and it's what set our team's kart apart. We opted to incorporate the driver's seat as a structural chassis member. Along with a CNC-cut Plywood construction, we produced a vehicle that was both light and supremely rigid.

Steering

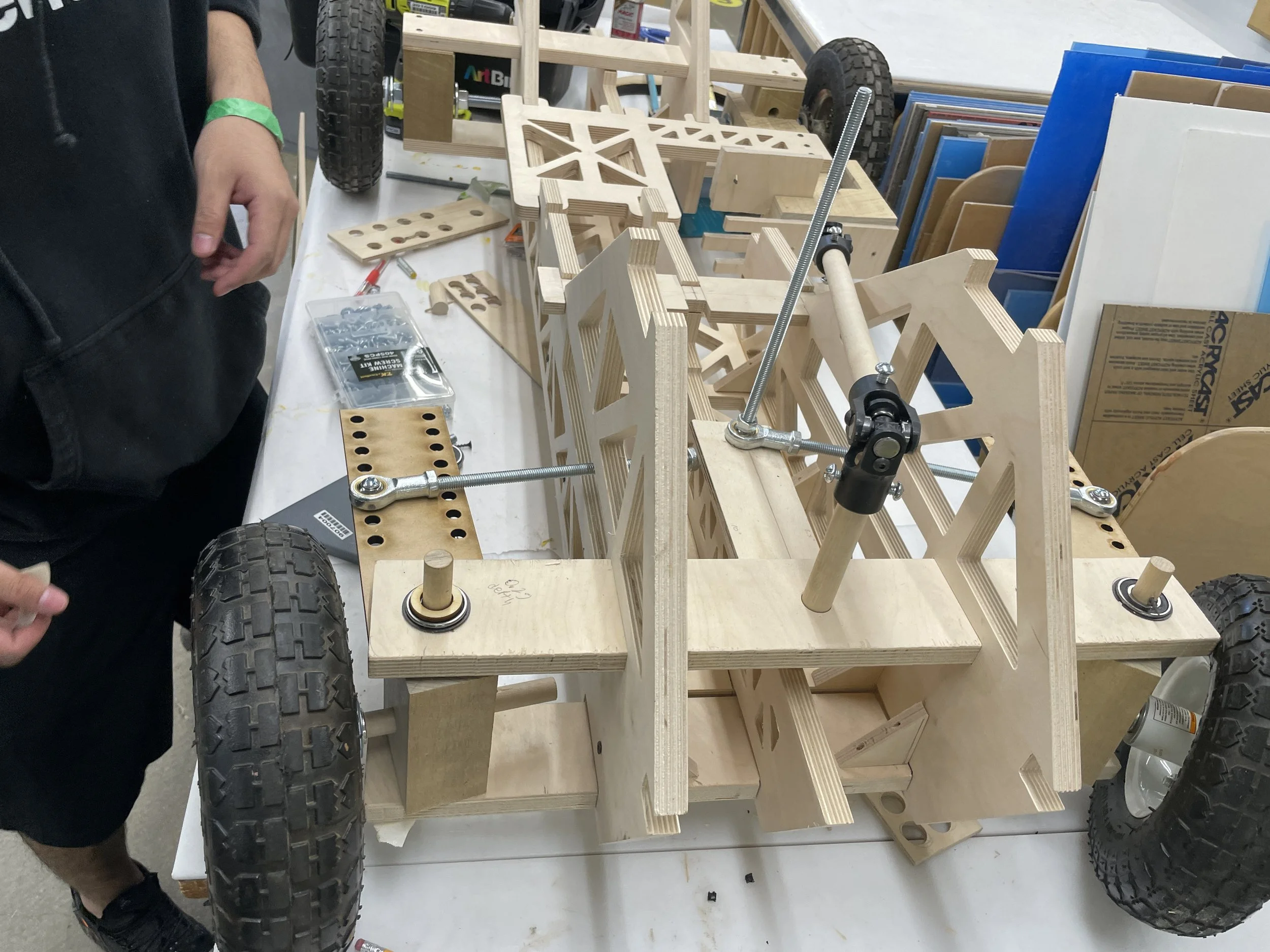

Providing reliable and accurate steering is not easy, and we designed a system optimized for the race our kart would have to run. Tight ratios and a U-Joint-based system gave us accurate and reliable steering.

Durability

Like any other vehicle, our karts would have to prove themselves in the real world. The 14-Week class culminated in a race designed to shake our karts apart. In early testing, our steering and throttle linkages proved especially susceptible to road vibration, with many alterations needing to be made before the final race.

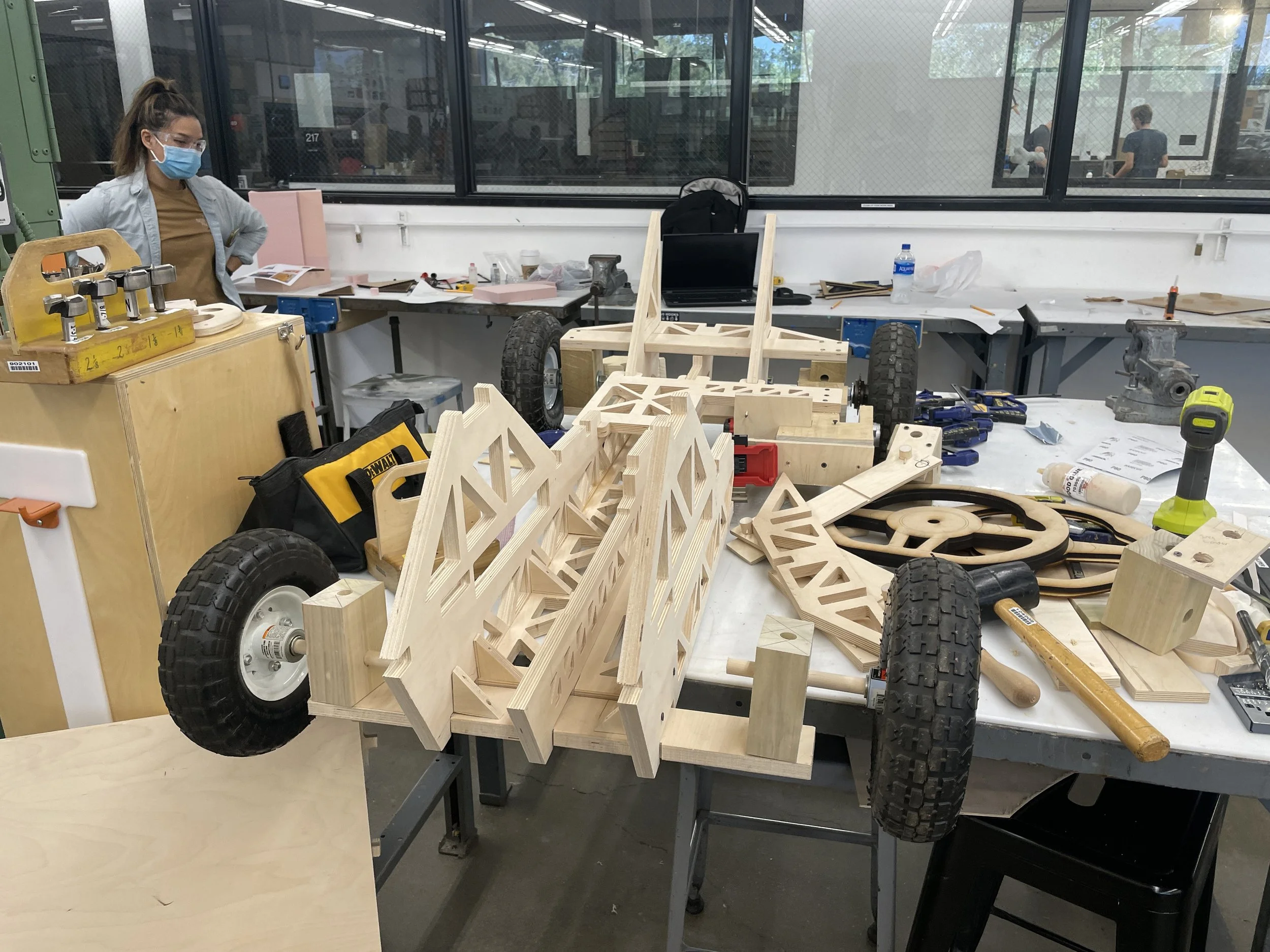

Chassis Mock-Up

To ensure our design was sound, we created a basic MDF model of the proposed chassis before starting the final product. I strongly believe in using tangible models to test concepts, rather than just relying on digital options. This approach proved particularly valuable in our project.

By building the mock-up, we could examine all the functional parts of the chassis and steering systems, without having to risk the cost and uncertainty of jumping straight from CAD to final production. The MDF model gave us the freedom to try different steering ratios, driving positions, and powertrain installations. It took us a few weeks of testing and adjusting, but eventually, we had our final design.

With the final design locked in, we were able to confidently move forward with the manufacturing of our chassis and steering.Once we had completed our testing on the MDF prototype, we converted our design into a CAD model using Solidworks. The next step was to send this model off to be CNC cut from 3/4 inch Baltic Birch Plywood, which is both lightweight and strong.

To further reduce weight, we opted for a triangular web construction for the chassis. This was a decision we made early on in the development process when we realized that the driver's weight would be a primary factor affecting the kart's handling. We knew that keeping the driver low and flat would be key, so we placed the driver's seat inside the chassis itself, making it a structural member of the kart.

Chassis Construction.

Powertrain & Steering Installation

Once we had finished constructing our chassis, we turned our attention to fitting the steering and powertrain components. These tasks demanded an extremely high level of precision to ensure that crucial features, such as the throttle linkages, motor gears, and steering joints, were correctly aligned.Motor & Wheel Balance Testing

Dealing with the vibrations caused by our powertrain was one of the most significant hurdles we had to overcome. Because of the inherent flexibility of plywood and some initial over-tolerance on our bearings, our drive chain would frequently slip. To get to the root of the problem, we conducted a static test to better understand the cause of our issues.Vehicle-Validation Drives:

By the end of eight weeks, we had a functional kart with all the necessary components installed, including the steering, brakes, seat, powertrain, and linkages. In theory, everything was ready to go, but as with any vehicle, we needed to test our design thoroughly. During our initial road trials, we encountered several problems, primarily caused by vibrations that unsettled many tight-tolerance components, such as the steering and throttle linkages.Troubleshooting

As we put our kart through its paces, we encountered any number of unexpected issues. However, we were pleased to find that our chassis held up exceptionally well. One of our most significant obstacles was motor overheating, caused by driveline inefficiency, along with failures of the steering and throttle linkages. Fortunately, since we had already established a solid foundation with our chassis, we were able to resolve many of these issues by making minor adjustments to various components without having to replace too many parts in their entirety.The class ended with an exciting five-lap autocross-style race against our classmates. Although some of the karts experienced mechanical failures, our team had a brief scare with our motor overheating, but we overcame it and took first place!Final Race.